To better serve clients and deliver OEMs’ demands for the test of high-power engines, ASIMCO Shuanghuan completed the upgrading and transformation of 4# lab in the first half of 2019. After the new lab is equipped with 7000kw electric dynometer system, the company has become the sole manufacturer with the test bench of this system in domestic piston ring industry. The core parts of this system are composed of the electric motor made by the U.S. Baldor, and Simens’s VDF, so they can perfectly meet the precision requirements in measurement and control process. The measurement and control system is equipped with 24-route pressure measurement, 24-route low-temperature measurement, 16-route high-temperature measurement and 15-route switches control channel to address the multi-channel measurement needs in bench tests. 4# lab is also equipped with AVL oil consumption meter, temperature control equipment and gas leakage measurement meter, to increase the measurement precision of fuel consumption, engine oil consumption and gas leakage that are closely related to piston rings. Meanwhile, the measurement and control system also consists of constant-temperature control device, constant-temperature engine oil device, inlet air-conditioning system, air inlet cooling device and exhaust treatment device, to guarantee the success of all the tests.

Because this test is conducted in strict compliance with Cummins’s standard and test conditions are complicated and challenging, there’s an extremely high requirement for the control performance of test devices and especially the control of fuel temperature changes, so as to ensure the temperature change within a wide range, and guarantee the timeliness of changes and the precision of temperature. However, the company’s existing equipment for controlling fuel temperature can’t meet the control needs. To undertake this test task, the company’s leaders made a decision in a short time to independently develop a new set of fuel temperature control equipment, and even completed the equipment installation and debugging before the test started.

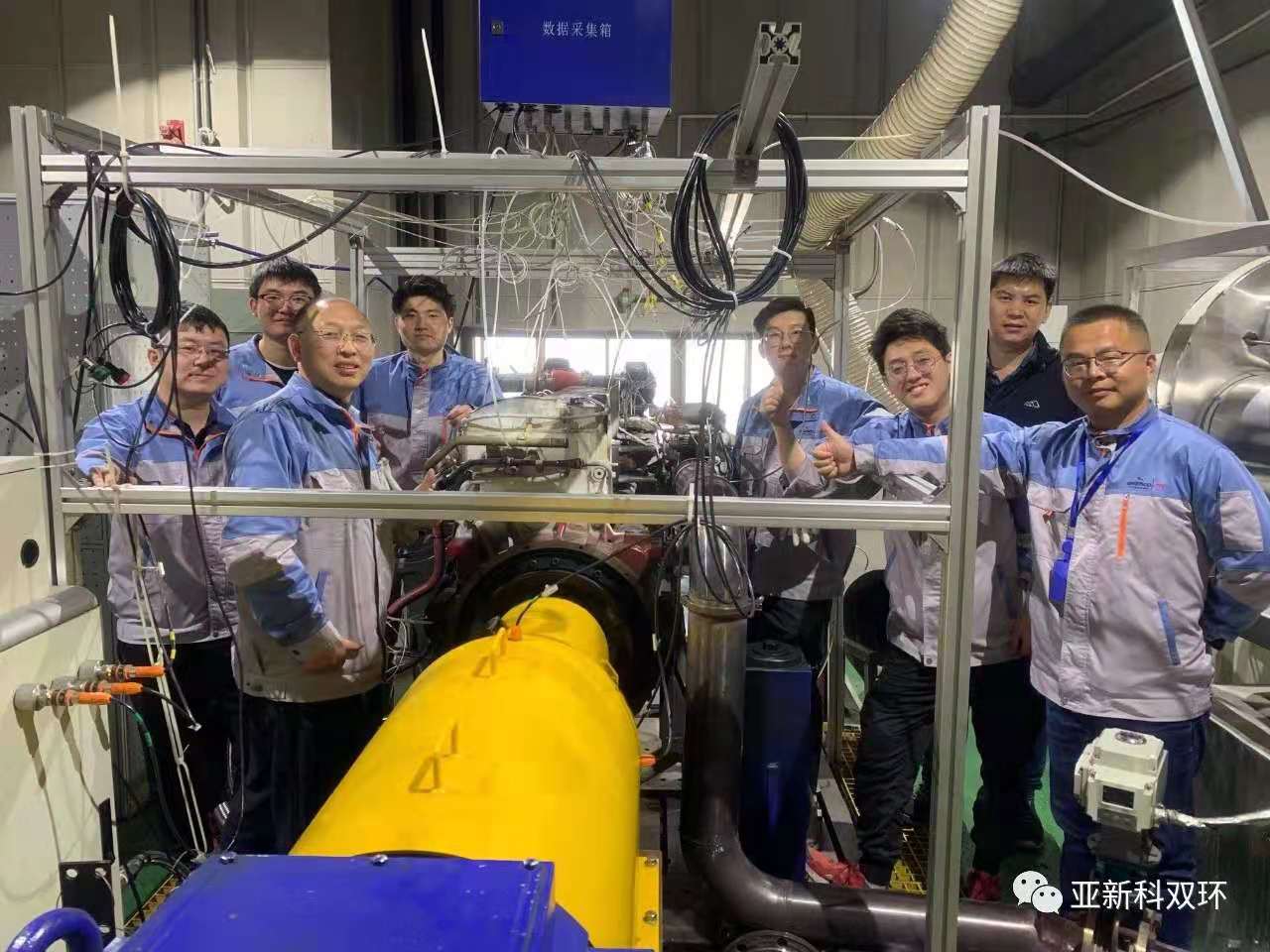

This 65-day bench test not only enhanced the quality of those employees concerned, but checked the performance of new bench test system. In the course of this test, the bench test team members stayed loyal to the style of plain living and hard working. They worked on a 12-hour work shift system and adopted the 7-day machine operation model to ensure the completion of test on schedule.

Guided by the client-oriented core value, ASIMCO Shuanghuan and Foton Cummins completed 1,000-hour durability test of X12 diesel engine with National VI Emission Standard.

The success of this test deepened the cooperation between two companies. While the development of piston rings for X12 diesel engine with National VI Emission Standard is promoted, the test performance of the company’s bench lab has been well recognized by Foton Cummins.

The company’s better engine bench test performance has laid a solid basis for the reliability and durability tests of high-power engines, demonstrated the company’s determination to develop piston rings of high-power engines in partnership with OEMs, and highlighted the company’s development philosophy “to be China’s leading auto components group with recognizable global impact”, in order to further sharpen the company’s core competence.